Offset Printing

This printing technique was the first printing technique used by Grafomed when the printing house first started its work.

In the process of offset printing, the ink is transferred directly from the plate onto rubber, and then onto a special type of printing paper, such as kunstdruk, muflon, label and offset paper. Due to its extreme adaptability with regard to printing materials, this technique is suitable for printing leaflets, posters, labels, brochures, memoranda, pads, magazines, books, calendars, maps, folders, postcards, invitations and other similar items.

The main features of offset printing are reliability of printing plates, unsurpassable flexibility with regard to ink and paper selection, additional options in finishing graphic editing, as well as long lasting, high quality images, which is why this technique is used for printing materials in large quantities.

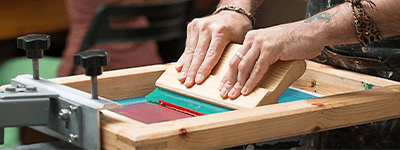

Screen Printing

One of the oldest printing techniques, offering a possibility of printing on almost all types of flat materials, which also makes it one of the most widely used techniques in printing.

In the process of screen printing, the print is made by pressing ink onto a printing form made with tightened silk on a wooden or aluminum frame. Due to its possibility of printing ink on different materials, such as glass, plastic, textile, metal, wood, ceramics and other surfaces of different shapes and purposes, it can be used in various industries.

It is especially used in the textile industry because the applications printed with this technique may be washed at 60 degrees Celsius without the reduction of quality and a lasting effect of the print. In this technique, the layer of ink inserted is the thickest in comparison to other printing techniques.

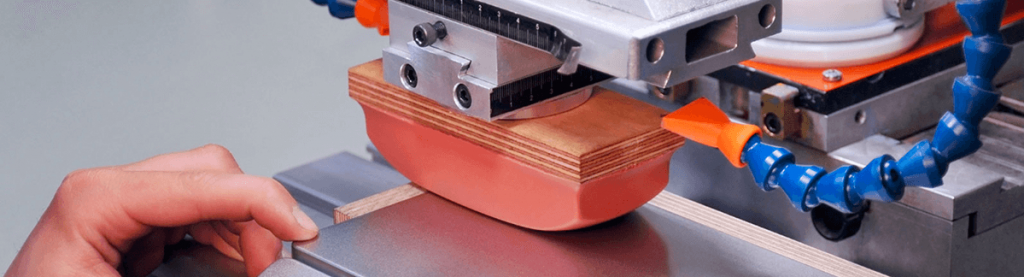

Pad Printing

By offering a possibility of printing on surfaces unthinkable before, this deep print technique has brought about a revolution in the printing business. Using this technique, the ink is transferred onto the object being printed from a specially designed pad made of rubber or silicone.

In pad printing, we can transfer 2D images on a 3D object, which is why this type of printing is used on bent or uneven surfaces of objects made of materials such as glass, ceramics, plastic, rubber and metal, although it is also possible to do printing on other shapes and surfaces as well.

This technique is a safe solution for pens, lighters, coffee mugs, ashtrays, keychains and other promotional materials. It is also used in the production of sports and medical equipment and toys.